昨日、2/5 R7.1.2の全モジュールがLSTCサイトにアップされ、公式リリースされた。

以下のリリースノートをさっと見てもわかるように、新機能は殆どなくて、R7.1.1に

対するFIX=バグ修正版である。

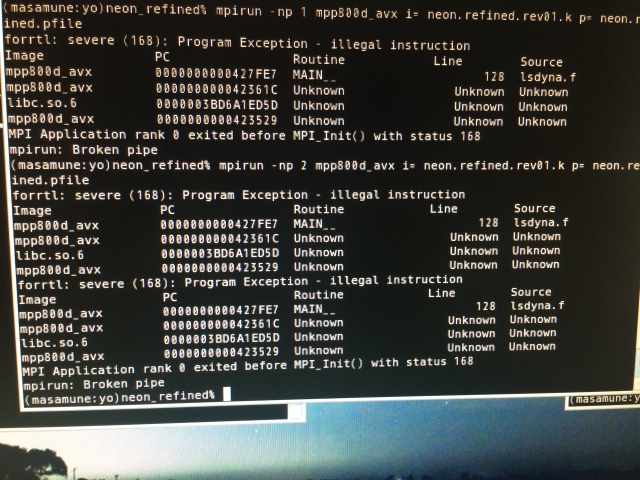

Windows64 と Linux64用のSMP版と、MPP版を(IBM Platform版のみ)を

弊社サイトにアップした。LSTCのサイトには、かなりの数のR8.0がアップされていて

R7.1.2は微妙な所だが、R7.1.1で不具合にブチ当たったら、R7.1.2を試してください。

マニュアルについても、2015/1/28付けのDRAFT版が公開されている。

今回から、Linux64 MPP版は、3種類選択可能となった。例えば倍精度版の場合

ls-dyna_mpp_d_r7_1_2_95028_x64_redhat54_ifort131_avx2_platformmpi.tar.gz

ls-dyna_mpp_d_r7_1_2_95028_x64_redhat54_ifort131_sse2_platformmpi.tar.gz

ls-dyna_mpp_d_7_1_2_95028_x64_suse102_pgi105_sse2_platformmpi.tar.gz

自分が持っているSUSE 10.2でも、CentOS-6 でもAVX2以外は全部動作した。

何が違うかというと、

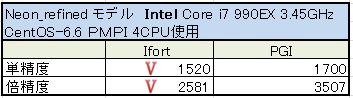

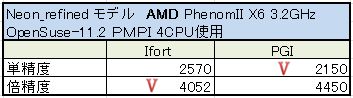

– ifort131 : Intel Fortranでコンパイルされており、Intel CPUで性能出る

– pgi105 : PGI Fortranでコンパイルさrており、AMD CPU向け

– avx2 .vs. sse2 : 最新のIntel CPUならavx2が速いはず。

性能比較テストについては、次のブログで紹介する予定。

リリースノート

—————————————————————————-

This file is revision 0 of the release notes for LS-DYNA version R7.1.2.

—————————————————————————-

Herein are summarized enhancements and bug fixes made since the

release of version R7.1.1.

These notes are arranged by topic. Understand that in many cases,

a particular note may have applicability to multiple topics, but in the

interest of brevity, each note is listed only under one topic heading.

The most recent User’s Manual (in three volumes) may be downloaded from

www.lstc.com/download/manuals.

________________________ *AIRBAG ___________________

Make VNTOPT in *AIRBAG_HYBRID work for A23.ge.0.

*DATABASE_ABSTAT:

Fix mdot_out for CPM chamber abstat database.

Bug fix for *AIRBAG_SIMPLE_AIRBAG_MODEL when using *INCLUDE_TRANSFORM.

The input parameters MU and A were converted correctly but the

pre-converted values were written to the dyna.inc file.

Implement *DELETE_AIRBAG for small restart.

________________________ *BOUNDARY ___________________

All *BOUNDARY IDs are offset by idroff when included by *INCLUDE_TRANSFORM.

Turn off pore air boundary condition (*BOUNDARY_PAP) during dynamic relaxation.

Fix incorrect rigid body velocities when using *BOUNDARY_PRESCRIBED_MOTION_RIGID_LOCAL

and *INITIAL_VELOCITY_RIGID_BODY.

Error terminate if *BOUNDARY_SPC_NODE_BIRTH_DEATH is applied to a node that

belongs to a rigid body.

*BOUNDARY_ACOUSTIC_COUPLING_MISMATCH:

Fix for spurious automatic coupling

with faces on free surface of *MAT_ACOUSTIC elements.

________________________ *CONTACT ___________________

MPP tied contact initialization:

Change a tolerance in groupable tied contact bucketsort

to match the non-groupable code, and fix the slave node

thickness used for beam nodes during initial search in

non-groupable contact to match groupable contact.

MPP groupable tied contact:

Honor TIEDPRJ in *CONTROL_CONTACT, and output messages about moved

nodes to match non-groupable tied contact.

MPP eroding contact:

Fix problem of every processor

participating in every eroding contact, even if they had none of

the nodes or elements. This caused scaling issues.

Fix for MPP contact force summation

as applied to shells with compressive thickness

behavior.

MPP beam to surface contact: remove “beam” node mass

from the penalty stiffness calculation when soft=1

is used, which matches SMP behavior.

Various fixes to intfor output for MPP contact.

MPP tied contact with adaptivity: if any master

segments get adapted, we were dropping any slave

nodes. Now flag these, and do a bucketsort for

just these nodes, to find their new tied location.

This allows tied contacts to work across adaptive steps.

MPP contact: fix routine that updates segment

Correct update of segment thicknesses for solid elements (every cycle) so that

it honors the OPTT parameter in *PART_CONTACT.

MPP: fix problem with *CONTACT_TIED_…_BEAM_OFFSET

and full deck restart: data for this contact type

was not properly written to the d3full file, making

full deck restart with this contact type impossible.

Fix problem when using *INTERFACE_LINKING together

with constrained tied interfaces. Nodes involved in

both are removed from the linking interface, but

this was leaving some internal structures out of sync,

sometimes causing nodes to be moved improperly.

MPP eroding contact: fix long standing bug that

might have improperly excluded some nodes from

contact.

Fix for MPP two sided force transducers with erosion:

shared nodes were only flagged on one processor, so

some forces along processor boundaries might not have

been counted to a force transducer.

Fix rarely triggered bug for beam thickness/stiffness

in MPP CONTACT_AUTOMATIC_GENERAL.

Fix for MPP groupable contact and implicit when there

are both constraint and penalty contact types.

Fix segmentation fault when using *CONTACT_GUIDED_CABLE.

Fix incorrect contact behavior when using *CONTACT_AUTOMATIC_GENERAL_INTERIOR for

beams with large differences in thickness and when the thinner beams are

closer to each other than to the thicker beams. Affects SMP only.

Fix incorrect contact thickness used for *CONTACT_ENTITY type 8 and 9 when

the contact thickness scale factor, g2, is non-zero.

Fix *RIGIDWALL_GEOMETRIC_FLAT_DISPLAY which incorrectly displayed the rigidwall

being penetrated by the slave nodes.

Add *CONTROL_CONTACT PENOPT=3 option for *CONTACT_ERODING_NODES_TO_SURFACE

for SMP.

Add contact friction energy to the SLEOUT database file for _2D_AUTOMATIC_SURFACE_TO_SURFACE

and _2D_AUTOMATIC_SINGLE_SURFACE contact.

Fix a 2D automatic contact bug that occurred if a segment has zero length. An

infinite thickness value was caculated by A/L causing the bucket sort to fail.

Fix an error in 2D automatic contact sliding interface energy reported

in glstat. The outputted value was about 2x the correct value.

Fix both the intersection and initial penetration reporting of segment based

(soft=2) contact when the shared constraint flag SHAREC is set for the contact.

The reporting of segment pairs that

share nodes will not be made when SHAREC=1, but can be reported if neighbor segment

checking is active.

Fix an MPP 2-surface force transducer blunder when segment based contact is used.

The symptom observed was a change in bucket sort behavior making the contact less

reliable for contact bewteen segments that are not on the same MPP partition when

2-surface force transducers were used.

Fix a full deck restart error with SMP segment based contact. A segmentation

fault was likely.

Add support for eroding, 2-surface force transducers when used with segment

based contact. Data is now updated so that when solid element erodes and new

segments exposed, force on these surfaces will be reported to the force transduders.

Stop segment based (soft=2) contact from reporting initial penetrations between segment

pairs that share nodes. Such segment pairs can only exist when SHAREC=1 as they

otherwise do not pass the bucket sort so do not make the list.

Fix an error with SMP consistency in the segment based (soft=2) contact

neighbor segment check activated by setting SFNBR>0.

Fix MPP full deck restart when using segment based contact.

It has been broken since rev 64900.

Fix the IGAP>2 option on *CONTACT Optional Card C for segment based contact for SMP and MPP,

and also the regular contact for SMP only. The count of cycles used the cycle number rather

than equilibrium steps. The problem in using cycle number is that there is no way to know how many

implicit cycles will occur prior to converging so it almost guarantees that the gap stiffness will switch

off during iterations. Also, the MPP segment based contact was not even working correctly with

cycles.

Fix a problem with segment based contact when used with dynamic relaxation and when the

solution was switched to implicit after convergence. The contact was scaled too soft causing

pass through.

Fix an error that could occur in segment based contact when some element(s) grow

very large. Due to a cap on the possible number of sorting buckets, it was possible

during a bucket sort for the majority of elements to be left in a few buckets

with most of the buckets remaining empty. This caused the bucket sort to

become extremely slow. It also had the potential to overrun a buffer causing a

segmentation fault. With this fix, the buffer will no longer overflow, and

there is also a fix such that when some elements grow large, the bucket sort

does not slow down very much.

*CONTACT_AUTOMATIC_SINGLE_SURFACE_MORTAR previously did not work

with beam elements but now works.

*CONTACT_FORMING_SURFACE_TO_SURFACE_MORTAR, *CONTROL_ADAPTIVE:

Look ahead adaptive simulation with forming mortar contact was broken at

some point, but is now fixed.

In initializing *CONTACT_FORMING_SURFACE_TO_SURFACE_MORTAR, reversal of contact segments

took a long time if slave and master part were far away from each other. This

algorithm is now improved. The typical situation when this is observed is

when trimming the blank, some master surfaces are far away so as to not be in play

but may still be in the contact definition.

________________________ *CONSTRAINED ___________________

Rework MPP support for *CONSTRAINED_MULTIPLE_GLOBAL

so that it works with more than just solid elements.

Fix MPP decomposition for some joint types.

Fix bug for *CONSTRAINED_SHELL_TO_SOLID — MPP only.

Fix input error when using large load curve ID for FMPH, FMT, FMPS in card 3

of *CONSTRAINED_JOINT_STIFFNESS with _GENERALIZED or _TRANSLATIONAL options.

Fix seg fault if using tables for FMPH of *CONSTRAINED_JOINT_STIFFNESS and if

the angle of rotation is less than the the abscissa of the table or load curves.

*CONSTRAINED_JOINT:

Fix for noncoincident joint node error warnings STR+65, STR+67, and

STR+72. Old data that used to run was error terminating.

Now, error termination happens only if both the old and new tolerances are exceeded.

Improve the precsion of spot weld constraints (*CONSTRAINED_SPOTWELD) to prevent possible

divide by zeroes when the inertia tensor is inverted. This affect the single precision

version only.

Fix for *CONSTRAINED_SPR2.

If the resultant normal directions of slave and master sheet

were not the same, high shear forces could develop initially.

________________________ *CONTROL ___________________

*CONTROL_TIMESTEP

Fix a bug whereby selective mass scaling (*CONTROL_TIMESTEP) was not properly initialized

in a simple restart.

________________________ *DATABASE ___________________

*DATABASE_NCFORC:

Modify output of ncforc file to support output in

a local coordinate system. If CID_RCF (field 8

on optional card C) is defined for a contact interface,

output the ncforc file in this coordinate system (so

that it matches the rcforc file).

MPP ncforc output: sum forces for slave nodes to fix possible

problems with shared nodes and symmetric contacts.

*CONSTRAINED_INTERPOLATION_SPOTWELD, *DATABASE_SWFORC:

Fix missing swforc output of spr welds — MPP only.

*DATABASE_BINARY_INTFOR:

Add support of surface energy output to intfor for contact types 4, 13 and 26

— MPP only.

*DATABASE_TRACER:

Fix bug for SPH tracer particle output — MPP only.

Fix incorrect output to disbout for discrete beams (*DATABASE_DISBOUT).

Fix stress/strain output to elout which were in local system instead of global

when EOCS=2 in *CONTROL_OUTPUT and CMPLG=1 in *DATABASE_EXTENT_BINARY.

Resolve the conflicting input by giving priority to EOCS.

Fix incorrect output 0.0 for history variable #3, bulkq viscosity, of solids to

d3plot when HYDRO.gt.0 in *DATABASE_EXTENT_BINARY and when equation-of-state is used.

Fix non-functioning *DATABASE_SBTOUT and *DATABASE_DISCRETE keywords.

Fix incorrect coordinate system used for strains output to d3plot when CMPFLG=1

in *DATABASE_EXTENT_BINARY and MAXINT<0 for orthotropic and anisotropic materials.

Fix inadvertent strain output to d3plot history variables when NODOUT=

ALL/ALL_GL/STRAIN/STRAIN_GL or INTOUT=ALL/STRAIN in *DATABASE_EXTENT_BINARY.

*DATABASE_ELOUT:

Fix elout stress output for shell element forms 23 and 24. The in-plane

averaging was incorrect causing wrong output.

Redo stress and strain output for thick shells. This should produce slightly different results

in the output files (not the solution) since some corrections were made to the local to global

transformation done for thick shell types 2 and 3. Forms 1 and 5 should not change.

*DATABASE_SECFORC:

Correct the sign of secforc data for thick shell forms 2, 3, and 5.

The force magnitude was correct but the sign wrong.

*DATABASE_ELOUT:

Fix eloutdet stress and strain output for thick shell form 5. It was

outputting nonsense.

Synchronize output time for intfor and d3plot databases.

Add *INTEGRATION… data to d3prop output.

Fix bug in d3plot if MSSCL option is defined in *DATABASE_EXTENT_BINARY.

________________________ *ELEMENT ___________________

Fix a bug related to using superelements (*ELEMENT_DIRECT_MATRIX_INPUT) with explicit

and having null columns in the linear algebra system

due to improperly constructed model.

Output of midside node data to d3xxxx databases was incorrect in MPP.

Fix a bug for detailed element output (eloutdet) for 6-node or 4-node solid when ESORT of *control_solid >0,

and for solid element type 15.

Fix “*** termination due to mass increase ***’ error when using mass scaling with

*ELEMENT_MASS_PART.

Fix fix incorrect output of initial stresses and initial strains to dynain for

thick shells.

Fix incorrect reading of TIME on Card 3 of *ELEMENT_SEATBELT_SENSOR, SBSTYP=3

when using long=s on the execution line.

Error terminate with message, STR+1296, if same node is defined multiple times in

*ELEMENT_MASS_MATRIX.

Fix seg fault when using shell formulation 18,20,21 for implicit eigenvalue

analysis and when triangular shell elements are present.

Fix input error when using *ELEMENT_SHELL_SHL4_TO_SHL8.

Fix time step being set to zero after full deck restart for problems with discrete

elements.

Fix input error during adaptivity cycle when using *PART_ANNEAL with adaptivity.

Add warning message, STR+1286, when no mid-side nodes are defined for shell

element type 23 and 24.

Fix thick shell form 5 when used in implicit solutions with non isotropic materials.

The stiffness matrix was wrong due to incorrect transformations.

Fix the implicit stiffness of thin and thick shells when used with laminated shell

theory by assumed strain (LAMSHT=3,4,5 on *CONTROL_SHELL). Elements were either failing

to converge or converging more slowly due to the failure to adjust the stiffness matrix to

be consistent with the assumed strains which are the basis for the forces on the right side of

the equation.

Improve the accuracy of the Belytshko-Schwer resultant beam (form 2) in single

precision.

*DATABASE_EXTENT_BINARY, CMPFLG:

Rework the thick shell stress output routine.

The 4-point in-plane elements (forms 2 and 3) could not correctly

average the stress from the 4 points when outputting only 1 and when outputting

in the composite material direction. Therefore, I changed the order of the output

calculations to do averaging in the material direction rather than the global system.

This change has no effect on the solution, and should only affect stress output in

the material direction, not the global direction.

*CONTROL_SOLID, ESORT:

Suppress sorting of tetrahedral acoustic elements into non-acoustic tets.

Fix the NLOC option on *SECTION_SHELL for the BCIZ triangle elements (ELFORM=3)

and DKT triangles (ELFORM=17).

The offset was scaled by the solution time step so typically the offset was

much smaller than expected.

Fix implicit thick shell form 2 when used with *MAT_058. Since rev 81390,

the stiffness matrix has been wrong and convergence impossible.

Remove an inappropriate warning message (INI+161) for cable elements with

*MAT_071.

Fix the rigid body inertia calculation for 2D axisymmetric element

types 14, 15, 44, 46, and 47. While this affects the mass properties reported

to d3hsp, it likely has no effect on the solution.

Modify shell element form 16. The node 1 coordinates are now subracted from the

other nodal coordinates in double precision so the precision of the element is

independent of location in space. Some minor recoding of this part of the code

makes it slightly faster on Xeon64 even though there are 9 additional subtractions

per element per time step. Single precision results with shell section 16 will be

slightly different with this change but single precision results should be closer

to double precision.

Fix the long option of *ELEMENT_SHELL_COMPOSITE_LONG. A mistake in

keyword reading caused an erroneous KEY+157 error message.

Fix thick shell form 3 when used with an equation of state.

The pressure was not properly accounted for in the stress calculation.

Fix thick shell form 5 when used with equations of state. The equation of state pressure was being

calculated for only the last integration point, creating nonphysical deformation.

The material models fixed are 8, 9, 10, 11, 15, 17, 65, 88, 155, and 224.

*CONTROL_SHELL:

Fix an initialization problem with laminated shell theory when the data has some

shell or thick shell parts that use *PART_COMPOSITE or *INTEGRATION_SHELL and some others

that do not. It was possible for lamatinated shell theory data to be clobbered causing

unpredictable element behavior.

Add z-stress calculation for thick shell forms 1 and 2 for the material types 15, 34, 60, 98, 108, 115, 122,

125, 130, 137, 165, 170, 172, 203, 204, 214, 222, 234, 235, 244, and 255. Prior to this change,

strange deformation would likely occur.

Note: This z-stress is not part of a full 3D stress update as it is for thick shell formulation 3 and 5.

________________________ *FREQUENCY_DOMAIN ___________________

*FREQUENCY_DOMAIN_SSD, _RANDOM_VIBRATION, _RESPONSE_SPECTRUM:

Fix the variable names for beam data written to elout_ssd, elout_psd,

and elout_spcm.

*FREQUENCY_DOMAIN_RANDOM_VIBRATION:

Fix problem where random vibration analysis was not activated after eigenvalue analysis due to

mismatch of termination time and time step size specified in *CONTROL_IMPLICIT_GENERAL.

*FREQUENCY_DOMAIN_FRF:

Fix a bug in writing Modal contribution factor.

*FREQUENCY_DOMAIN_ACOUSTIC_BEM:

Fix memory allocation for pressure output array in bem acoustic analysis for the case nfreq=0.

*FREQUENCY_DOMAIN_ACOUSTIC_FEM:

Fix a bug in initialization of the load curve in FEM Acoustics, when the boundary condition

is given by transient analysis.

*FREQUENCY_DOMAIN_RANDOM_VIBRATION:

Fix a bug in computing rms of displacement, in case the PSD integration provides a negative area.

*FREQUENCY_DOMAIN_RANDOM_VIBRATION:

Fix a bug in running random vibration with time history load.

*FREQUENCY_DOMAIN_FRF, *FREQUENCY_DOMAIN_SSD:

Fix a bug in running frf and ssd with pressure loading.

*FREQUENCY_DOMAIN_RESPONSE_SPECTRUM:

Fix a bug in running response spectrum analysis, related to scaling of modal stresses.

Fix a bug in outputing solid types with midside nodes to binary frequency domain databases

when tet10=1 in *CONTROL_OUTPUT.

*FREQUENCY_DOMAIN_FRF:

Fix bug in running frf with 8-node quadratic quadrilateral shells.

Fix a bug in running frf when 10-noded tetrahedrons are present.

________________________ *INITIAL ___________________

Fix incorrect initial velocities when using *INITIAL_VELOCITY_GENERATION with

irigid=1 and *PART_INERTIA with xc=yc=zc=0 and nodeid>0 with *DEFINE_TRANSFORMATION.

Fix incorrect initial velocity when using *INITIAL_VELOCITY_GENERATION with

NX,NY,NZ defined and also *PART_INERTIA is used.

Fix incorrect start time for initialization of velocities when PHASE=0 in

*INITIAL_VELOCITY_GENERATION and *INITIAL_VELOCITY_GENERATION_START_TIME

is present.

Fix stress initialization with *INITIAL_STRESS_SECTION for tetahedron formulation 17.

*INITIAL_VELOCITY:

Fix rigid body velocity initialization for the case of pure translation.

Nonzero stress could be generated in parts that shared nodes with rigid bodies. The

problem was that the calculation to initialize rigid body velocities and rotations is

susceptible to round-off error such that the rigid body has tiny initial rotations which

lead to stress in the deformable elements.

*INITIAL_STRESS

Fix thick shell stress initialization which was improperly initializing the stress data

data for for thick shell forms 2 and 3.

Also correct the warning message for shell and thick shell stress initialization

when the number or location of thickness integration points in the initialization data does not

match the elements to be initialized. This is messages INI+143, INI+144, INI+145, INI+146, and

INI+147. I also made a similar correction for INI+213 which is related to initial failure.

________________________ *LOAD ___________________

Add load curves for dynamic relaxation for *LOAD_THERMAL_VARIABLE.

Fix input error when using *LOAD_MOVING_PRESSURE with >100 Card 2’s.

Fix incorrect stress initialization with dynamic relaxation when using

*LOAD_SEGMENT_SET with AT.ne.0.

*LOAD_SEGMENT; *CONTROL_ADAPTIVE:

Fix bug whereby loads on non-adapting parts were affected when

3D adaptivity is invoked.

________________________ *SENSOR ___________________

Moment of rotational discrete element can be traced by *SENSOR_DEFINE_ELEMENT,

with ETYPE=DISC-ELE and CTYPE=FORCE

SENSOR referred to by *DEFINE_CURVE_FUNCTION returns a value of:

– “0” when the status of ctrlid is OFF and TYPE is not FUNCTION,

– “TYPEID” when the status of ctrlid is OFF and TYPE is FUNCTION

Fix a bug when using *SENSOR_DEFINE_FORCE to trace the pressure of *AIRBAG_ADIABATIC.

________________________ *MAT ___________________

Fix bug in hysteretic behaviour of reinforcement in *MAT_174. Occasionally,

it was possible for the Bauschinger effect on re-loading to

be lost – for that half-cycle, the behaviour would become

elastic-perfectly-plastic. This bug occurred only rarely.

MAT_082_RCDC:

– Fix bug where damage from load curves was incorrectly calculated for solid elements.

– Fix error in scaling of averaged nodal pressure for solid formulation 13.

Check diagonal terms of C-matrix of *MAT_002/MAT_{OPTION}TROPIC_ELASTIC and

error terminate with message, STR+1306, if any of them are negative.

Fix incorrect stress initialization of *MAT_57/MAT_LOW_DENSITY_FOAM using dynain

file with *INITIAL_STRESS_SOLID when NHISV is equal to the number of history

variables for this mat 57.

Fix error when using *MAT_144/MAT_PITZER_CRUSHABLE_FOAM with solid tetahedrons type 10.

Fix incorrect writing of material data to dyna.str for *MAT_SEATBELT when

using long=s on the execution line.

Fix out-of-range forces after dynamic relaxation when using VP=1 for

*MAT_PIECEWISE_LINEAR_PLASTICITY and non-zero strain rate parameters, C & P, and

the part goes into plastic deformation during dynamic relaxation.

Fix incorrect *MAT_PLASTICITY_COMPRESSION_TENSION/MAT_124 yield stresses for shells

when SRFLAG=2. The yield stress was not scaled correctly according to strain rate

curves, LCSRC and LCSRT.

Fix incorrect results when using *DEFINE_TABLE for LCSS of

*MAT_89/MAT_PLASTICITY_POLYMER.

Fix incorrect results when using *MAT_MUSCLE/MAT_156 with *PART_AVERAGED for the

truss elements.

Fix seg fault when using *MAT_NONLOCAL with nhv > 16 and also output

warning message, STR+1291, if the largest history variable # is > than

the number of stored history variables(including plastic strain).

Fix effect of shear correction factor, SHRF, in *SECTION_SHELL and *PART_COMPOSITE

on *MAT_ORTHO_ELASTIC_PLASTIC/*MAT_108.

Fix incorrect results when using *MAT_JOHNSON_COOK/*MAT_15 with thick shell

formulations 3 and 5.

Modify *MAT_221 (MAT_ORTHOTROPIC_SIMPLIFIED_DAMAGE) to correct the damage

behavior. Prior to this fix, damage was applied to new increments of stress, but

not the stress history, so matrial softening was not possible. Since damage is

applied to the constitutive matrix, it was necessary to switch the stress update

from a rate form (rate-of-deformation) to an total strain form. The total strain

used is the accumulated increments from the rate-of-deformation. Since the material

behavior is elastic, the results are about the same except when damage occurs.

Fix error in inititialization that could cause a problem with *MAT_FABRIC’s RGBRTH

parameter. If there was more than one fabric material model, and all data was the

same except for RGBRTH, the materials could be merged causing the RGBRTH of the

second material to be ignored.

Add support for *MAT_096 for several solid element types including 3, 4, 15, 18, and 23.

Also, reduce the liklihood of numerical overflow in *MAT_096. This is really a bug fix

because we did not terminate cleanly.

Fix the use of uninitialized curve slope values in the implicit element stiffness

matrix when the 6 DOF spring material (*MAT_119) is used with beam form 6. The slopes

have now been set to zero for degrees of freedom for which no curve is defined.

Enable 5 newer materials and/or thick shell materials to be used with the

material angle field of *PART_COMPOSITE or *PART_COMPOSITE_TSHELL. The new

materials are 5 40, 136, 219, and 253.

Fix type 6, 7, 9 hourglass control for *MAT_187 and *MAT_232.

Fixed calculation of failed layers in reading SOFT (crashfront) parameter for *MAT_261/262.

Fix keyword reading of *MAT_124 constants EC and RPCT.

It was not working if they were defined under *PARAMETER.

New option for strain rate averaging in *MAT_083.

Exponential moving average can be invoked by setting SRAF<0,

where abs(SRAF) represents the degree of weighting decrease.

New option for unloading behavior in *MAT_083.

If TBID<0 or HU>0 (“damage formulations”), unloading is rate dependent

by default. This can now be changed to “rate independent” by new

input parameter RIULD on Card 5, Column 2. This seems to help noise

reduction in some cases.

Added new option to *MAT_106 for shell and solid elements.

Load curve LCFAIL (Card 4, Column 4) refers to

plastic failure strain as function of temperature.

Fix combination of implicit analysis with *MAT_057

and solid element types 4, 16, or 17.

Add new parameter “EXPON” to *MAT_083 on optional card 5, column 1.

This is an exponent in the damage function for unloading when HU>0:

d = (1-HU) * ( 1 – (Wcur/Wmax)**SHAPE )**EXPON

Add a new failure indicator as history variable #10 to *MAT_123.

Add triaxiality as history variable #11 to *MAT_123.

Fix for combination of standard failure criteria and GISSMO

with LCREGD>0 in *MAT_ADD_EROSION.

Correct internal energy calculation in *MAT_ADD_EROSION

damage model GISSMO for thin and thick shell elements.

Fix for *MAT_ADD_EROSION, damage model GISSMO. Option NUMFIP<0

was not working correctly for the combination with *MAT_036.

Fix for *MAT_083 when unloading is controlled via TBID<0.

In rare cases it was possible that the lowest curve in the table

was used for rate dependent stress evaluation, but it should only

be used for unloading response.

Parameter SCLMRR of *DEFINE_CONNECTION_PROPERTIES was not working

for spotweld assemblies/clusters. This is now fixed.

Correct problem with the number of history variables

in user materials with solid elements when options INTOUT/NODOUT

of *DATABASE_EXTENT_BINARY are set to “STRAIN” or “ALL”.

Fix a bug that prevented *MAT_POWDER from being compressed beyond a certain point.

________________________ ALE ___________________

Fix bug for *ALE_ESSENTIAL_BOUNDARY when defined by parts; wrong surface segments

generated for pentahedral and tetrahedral elements.

________________________ SPH ___________________

*DEFINE_ADAPTIVE_SOLID_TO_SPH:

Fix bug affecting tet and wedge solid elements adaptively transformed into SPH particles.

________________________ *IMPLICIT ___________________

Fix reading of d3kil file to allow for implicit switches

with more than 4 characters.

*CONTROL_IMPLICIT_INERTIA_RELIEF, *CONTROL_DYNAMIC_RELAXATION:

Allow the case of dynamic relaxation with implicit

using inertia relief and then switching to explicit.

Fix Implicit’s treatment of rigid bodies after restart of an

adaptive simulation (*CONTROL_ADAPTIVE).

*CONTROL_IMPLICIT_MODAL_DYNAMIC:

Correct reading of d3eigv database for modal dynamics in the

presence of higher order elements and tshell elements.

*CONTROL_RIGID:

Turn off LaGrange Multiplier Treatment of joints when Implicit is active.

*CONTROL_IMPLICIT_MODES:

Enhance the computation of the superelement inertia matrix in the presence of

rigid bodies. The mass matrix multiplication has to involve the mass on the

slave nodes for this computation which is unlike other applications in LS-DYNA.

________________________ Thermal ___________________

*CONTROL_ADAPTIVITY:

MPP fix for possible deadlock

when using adaptivity together with thermal coupling.

Enable thick shells to work with thermal materials. A flaw in the calculation

of temperatures meant that thermal materials would not behave correctly

except when done using *MAT_ADD_THERMAL_EXPANSION.

Fix thick shell elements when used with thermal materials and there is a variation in

the temperature field. The temperature variation in the element was not being calculated and

all integration points were assigned the same temperature.

Flux was not being calculated for *MAT_THERMAL_CWM

when a time function was used for CWM.

Fix improper data in d3plot causing problems when using *LOAD_THERMAL_D3PLOT.

________________________ MPP ___________________

Incorporate new element cost routines for purposes of decomposition.

New pfile options are:

decomp { newcost } = use new element costs

decomp { shellcosts filename } = read shell cost info from ‘filename’

decomp { solidcosts filename } = read solid cost info from ‘filename’

There is no facility for generating the shellcosts or solidcosts

data files — those will have to be done with the R8.0 or later

versions.

Fix issue with full deck restart in case

some processors do not have any contact interfaces.

Fix MPP decomposition issue

in case there are 2D sliprings.

Fix MPP adaptivity for very large models: the

reading of the adaptive dump file was not

working properly for files over 8GB.

Fix a bug related to *PARAMETER and restart

that was resulting in parameters not being

properly redefined on the first restart in MPP

on processors other than 0, or on the second and

subsequent restarts in SMP and MPP (all processors).

This is only a problem if there are

*DEFINE_CURVE_FUNCTION definitions that use

parameters.

Fix MPP problem of creating a pre-decomposition file

while using a jobid.

If a structured output file is being created,

echo a copy of all pfile data (pfile + internally

generated from the *CONTROL_MPP keywords) to a file

named <jobid>pfile.log. This makes it easy for

decomposition related keywords to be used with

the structured version of the file.

*CONTROL_DYNAMIC_RELAXATION:

MPP fix for dynamic relaxation

initialization in polar coordinates.

Fix INTERFACE_LINKING in MPP.

For small restart job, use the memory size stored in dump file instead

of memory specificed on command line.

*DEFINE_HAZ_PROPERTIES:

Fix bug for HAZ input deadlock — MPP only.

*DEFINE_SPH_DE_COUPLING:

Fix bug for SPH + DES coupling — MPP only.

Add support for *DEFINE_DE_BY_PART — MPP only.

Overrides *CONTROL_DISCRETE_ELEMENT for specified part IDs.

Fix hang up when using *DEFINE_CURVE_FUNCTION with element function

BEAM(id,jflag,comp,rm) and running MPP with np>1.

Fix bug whereby for *CONTROL_MPP_IO under Windows OS, user

had to have administrative privileges to write tmp file on

root drive. For Windows only.

________________________ Miscellaneous ___________________

Fix problem of LOCAL parameters and adaptivity.

Because the adaptive process merges all the include files,

the “locality” of these was being lost. Two new keywords are

introduced (*PARAMETER_PUSH and *PARAMETER_POP) and are used

to work around this issue.

When using *INCLUDE_TRANSFORM, offset IDs of sensors, nodes, elements and parts referred

to in an included *DEFINE_CURVE_FUNCTION by IDROFF, IDNOFF, IDEOFF and IDPOFF,respectively.

Fix a bug for *SET_SEGMENT_GENERAL that happens when option=PART is used to

define segment set of a part of solid element

Fix incorrect shell set generated when using *SET_SHELL_GENERAL with OPTION=PART.

Fix *NODE_MERGE_SET which gives incorrect set of nodes.

Fix input error, KEY+517, for null part set when using *SET_PART_LIST_GENERATE and

*PART_MOVE together.

The delay time, TIME3, in *DEFORMABLE_TO_RIGID_AUTOMATIC is not correctly

implemented. The TIME3 in the last *DEFORMABLE_TO_RIGID_AUTOMATIC was used

instead.

Fix incorrect sign of result returned from *DEFINE_CURVE_FUNCTION’s

JOINT(id,jflag,comp,rm) if jflag=1.

Fix input error when using Q=REMAP.

Error terminate the input if the abscissa values of *DEFINE_TABLE are the same.

Fix input error when parameter is present in cards following *COMMENT

keyword and before the next ‘*’ keyword.

Fix NaNs triggered by 100th percentile *COMPONENT_GEBOD.

Make improvements and corrections to long format input.

Fix bug if *DEFINE_CURVE is used to define adaptivity level.

See IREFLG in *CONTROL_ADAPTIVITY.

If any node/element is encrypted and PSETID in *DATABASE_BINARY_D3PLOT is set,

we will disable dynain output.

*CONTROL_ADAPTIVE:

Fix bug whereby element IDs of non-adaptiing parts changed when

3D adaptivity was invoked.